We are aware of the importance that companies have in maintaining high quality in their products.

Just as important as taking care of quality ought to be complying with the regulations regarding it, so we strive daily in order that iTunaFish achieves the specifications of the IFS Food Standard for our clients

iTunafish contemplates the necessary processes to obtain the

IFS Food certification (International Featured Standards) recognized by the Global Food Safety Initiative (GFSI) that guarantees the legality, safety and quality of the products produced.

-

- Management of versions of the quality and food safety manual, storing who, when, what is modified and the reason for them. In addition, it allows access to the latest version of the document for inspections.

- A HACCP system (Hazard Analysis and Critical Control Points) is established for product quality assurance. Critical points are identified and monitored.

- To ensure the HACCP system, the processes to which the products can be subjected are identified, allowing for their control.

- For the adaptation to the HACCP system, the following actions have been implemented:

- Description of the product. Including:

- Composition

- Physical, organoleptic, chemical and microbiological parameters

- Treatment methods

- Packaging

- Durability

- Storage conditions, method of transport

- Determination of the use of by-products of each product.

- Storage of the product sheet (PDF). Managing who modifies it, when, and the reason.

- Description of the product. Including:

- Determination of control points and their management. For this, an inspection sheet is available, establishing the parameters to be controlled, the date and user who performs it.

- Control of corrective actions of the control points, as well as of the products indicated as non-compliant. This allows for the control of these corrective actions indicating the date of resolution and all the necessary data to ensure quality.

- Control of HACCP system verification procedures. It allows a control of them, indicating the corrective actions to be carried out in case they are necessary.

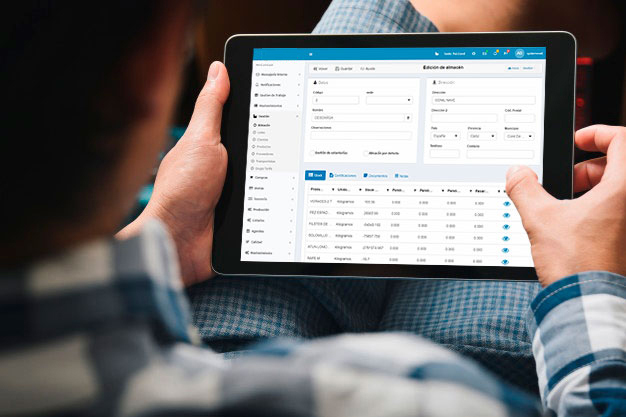

In short, iTunaFish, our ERP software for companies in the fisheries and frozen fish sector, has the necessary functions and features required to guarantee customer and consumer confidence in its transparency throughout the supply chain.

Other articles you may be interested in: Traceability